Inrotech-C&B

INROTECH-C&B FOR OFFSHORE WIND INDUSTRY

Inrotech-C&B is an intelligent welding robot system for demanding MIG/MAG welding automation purposes especially intended for offshore & wind energy industries. The Inrotech-C&B robot is equipped with Inrotech’s unique WeldLogic Technology and runs fully automatically throughout the entire process.

The robot initially locates, scans and analyzes the welding groove, thereafter, plans and performs the weld without any interaction required from the operator.

GET TO KNOW OUR INROTECH-COLUMN&BOOM

During the welding process the robot automatically cuts the wire, cleans the welding torch and deslags the groove to ensure a clean weld. Additionally, the robot ensures that the temperature stays within the customer’s specifications. The robot is able to operate unmanned for more than 10 hours, making it a cost efficient solution.

INTERESTED IN HEARING MORE ABOUT OUR INROTECH-C&B ROBOT?

NO PROGRAMMING, NO TRANSFER OF CAD-DRAWING

ADAPTIVE MULTIPASS WELDING

The Inrotech-C&B is ideal for automatic downhand multipass welding of plate joints and longitudinal joints on cans with a plate thickness up to 150 mm, while automatically taking tolerances of the weld groove into consideration.

The scanner house is equipped with a laser scanner and temperature sensor for measuring the interpass temperature

DURING THE WELDING PROCESS

🔧 𝐓𝐨𝐫𝐜𝐡 𝐒𝐞𝐥𝐞𝐜𝐭𝐢𝐨𝐧: The robot automatically determines the appropriate torch size for the weld, considering factors such as joint spacing, collision checks, welding angles, and other relevant parameters.

✂️ 𝐖𝐢𝐫𝐞 𝐂𝐮𝐭𝐭𝐢𝐧𝐠 & 𝐂𝐥𝐞𝐚𝐧𝐢𝐧𝐠: After each weld, the wire is cut, and the gas cup is cleaned with compressed air.

💨 𝐃𝐞𝐬𝐥𝐚𝐠𝐠𝐢𝐧𝐠 𝐏𝐫𝐨𝐜𝐞𝐬𝐬: The robot then returns to the workpiece to deslag the weld by using compressed air, ensuring surface silicates are reduced.

📡 𝐒𝐜𝐚𝐧𝐧𝐢𝐧𝐠 & 𝐃𝐞𝐭𝐞𝐜𝐭𝐢𝐨𝐧: Next, the robot re-scans the groove to detect any deformation or shrinkage.

🔥 𝐇𝐞𝐚𝐭 𝐂𝐨𝐧𝐭𝐫𝐨𝐥 & 𝐏𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧: Monitoring Interpass Temperature.

🔄 𝐑𝐞𝐜𝐚𝐥𝐜𝐮𝐥𝐚𝐭𝐢𝐨𝐧 & 𝐎𝐩𝐭𝐢𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧: This includes recalculating the weldplan with number of layers, passes, welding parameters etc.

✅ 𝐐𝐮𝐚𝐥𝐢𝐭𝐲 𝐀𝐬𝐬𝐮𝐫𝐚𝐧𝐜𝐞: The result is consistently high-quality welds.

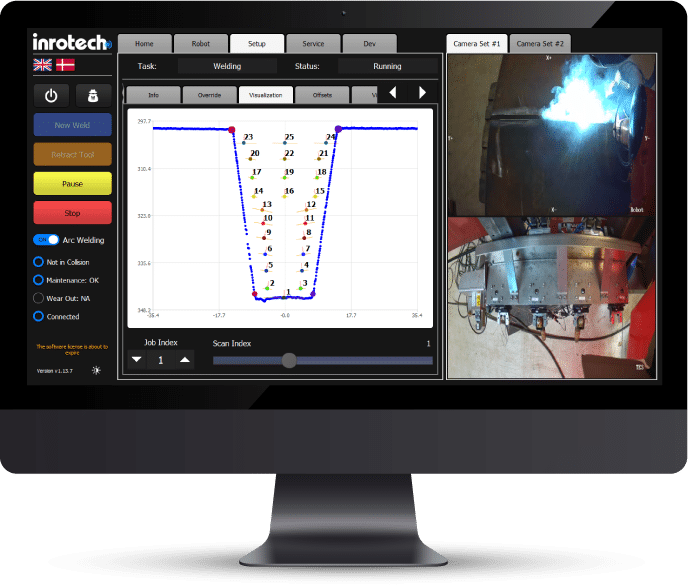

USER-FRIENDLY INTERFACE

The user-friendly interface gives you full control over the robot from one single touch screen, while providing accurate report from the process, saving all welding data for later inspection. The Inrotech-C&B is provided with remote-access for online support.

Subscribe to Inrotech newsletter and get information about our latest news and releases.