The need to remain competitive in the shipbuilding market has led to the development of new fabrication techniques, processes, and working practices. Carl Erik Skjølstrup, Naval Architect and Regional Sales Manager at Inrotech, explores the positive role that mobile welding robots play in improving production efficiency in the shipbuilding industry.

“Over recent years, shipbuilding has witnessed a substantial increase in the demand for gross tonnage, with shipyards in Canada, the USA, UK, Australia, and China experiencing a significant surge in shipbuilding orders. Consequently, shipyards have had to reassess their approach to welding to meet new production targets and cost considerations,” says Skjølstrup.

As a means of underlining the importance of welding automation in shipbuilding, Sumitomo Heavy Industries, Oppama Shipyard, provided information on the breakdown of various elements of ship construction. It concluded that welding represents around 25-28% of all shipbuilding operations.

Therefore, the shipyard’s competitive edge can be significantly enhanced if they can produce welds more quickly and with higher quality than their competitors. This is especially significant when 28% of ship manufacturing cost derives from welding these vessels. As the global shipbuilding market has grown, the availability of labor to meet these new demands has become problematic in many countries worldwide. This situation has generated an urgency to improve welding and fabrication processes to accommodate the lack of skilled workers and the increased economic market demands.

The primary theme of these improvements is simple: welding processes need to be modified or redeveloped, and the use of automation in welding has become mandatory in order to stay competitive.

Intelligent mobile welding robots in shipbuilding

The days of manually programmed robots are thankfully passed since long, and the need for offline programming, the transfer of CAD drawings, manual selection of objects, and back-end engineering support are also things of the past.

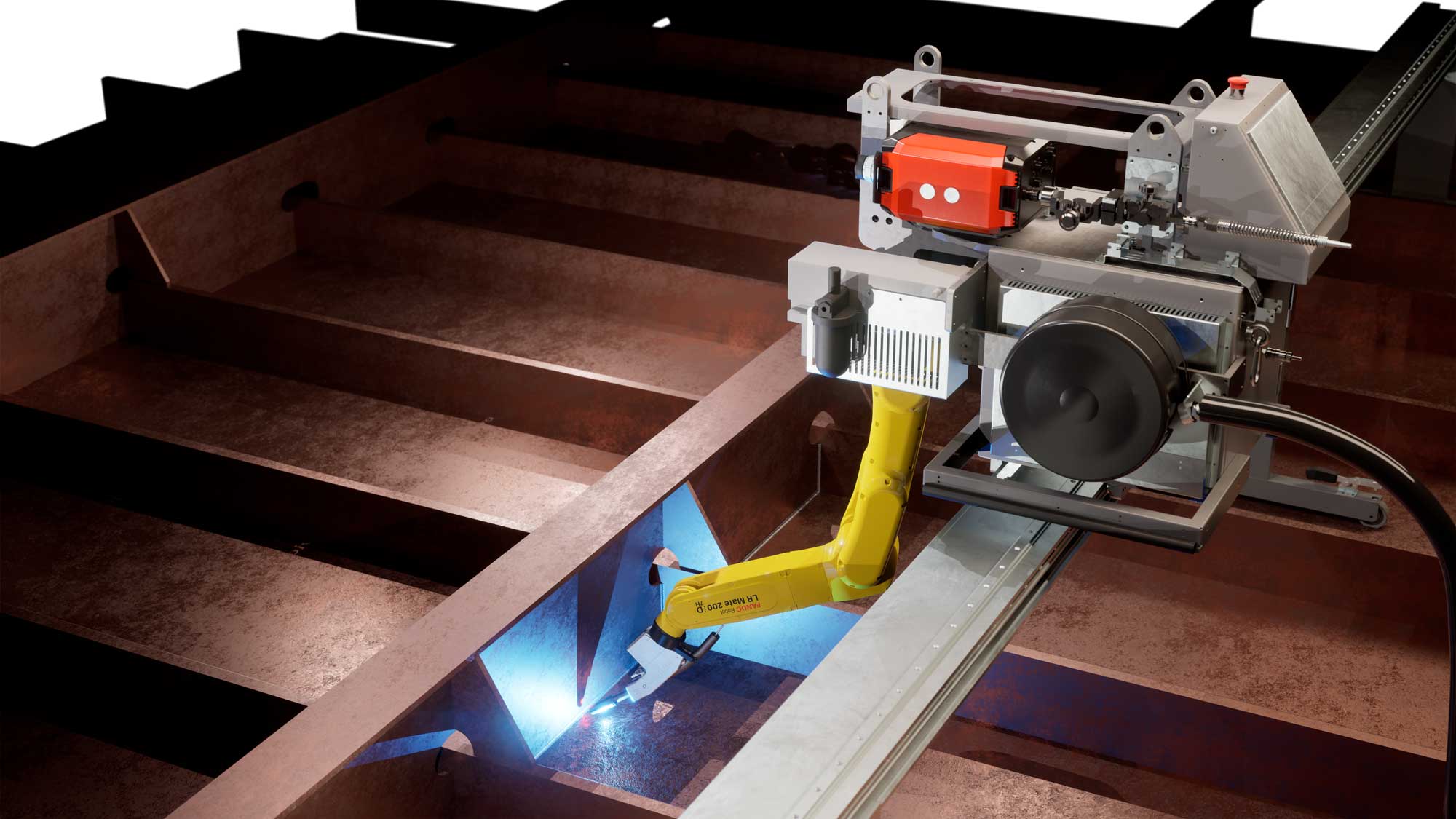

“Inrotech has been working to solve a well-known problem with mobile welding robots that several shipyards and robot suppliers have not been able to solve so far. The welding technology, Inrotech-SensLogic, is specifically developed for fillet welding of recognizable features, making repetition and kilometers of fillet welding possible and easy without the need for CAD drawings and programmers,” continues Skjølstrup.

Inrotech-Classic, based on SensLogic Technology, is consequently a flexible solution compared to big gantry systems that typically require designated adaptations to production areas and facilities. Using big gantry systems also require extensive training for your operators, extensive education of back-end engineers for OLP, and offline programming. In contrast, Inrotech’s mobile solutions require only a couple of days of introduction before the setup is implemented and ready to go.

By deploying scalable solutions such as Inrotech-Classic in your production, you can quickly implement numerous robots without disrupting your current production flow. Here are some of the main benefits of deploying mobile welding robots in shipbuilding:

✅ Arc ratio: High welding arc time and multiple robots per operator at low investment

✅ Arc density: A high number of welding arcs per section/block at low investment

✅ Introduction in existing facilities: No changes to the production layout and facility are required

✅ Introduction during running production: Swift implementation without disrupting/interrupting the production flow

✅ Adaptable to fluctuations in production workload; the robots are not tied to specific tasks through pre-made programs

✅ Flexibility in workflow: The operator or the shop foreman can allocated all robots to one section or spread them across several sections

✅ Ease of use and low operator skill requirements

✅ No engineering support and no dependency on CAD data and quality

✅ A proven track record from numerous shipbuilding applications worldwide

We always recommend shipyards to prioritize the implementation of welding automation in a sequence with the highest probability for success and the largest impact versus effort and facility changes. This solution has benefited Oshima Shipyard.

“After deploying approximately 20 of Inrotech’s mobile robots, we have experienced several advantages, most notably a dramatic increase in productivity. We have continued to invest in Inrotech welding solutions and have consistently experienced high welding quality from the robots. At Oshima Shipyard, we are currently rethinking our goals with higher standards of what we can achieve thanks to Inrotech’s welding robots.” – Mr. Masahiro Shiraki, Project Manager, Oshima Shipyard, Japan.

How does Inrotech-Senslogic technology works?

SensLogic technology is a combination of geometric sensing and logic recognition, which identifies the type, size, and exact position of profiles, stiffeners, brackets, and so on. The technology differs from other known solutions in that small mobile welding robots are used, which move in relation to the workpiece. The robot is equipped with a laser scanner, which scans the weld joint and creates a 3D image of it.

Based on this image, the built-in logic plans the course of the weld; it adjusts welding parameters according to the position, design, and degree of filling of the weld and determines the position of the individual strand, so that the weld joint ultimately achieves a uniform filling. Besides being simple to use, SensLogic can also, to a large degree, work with wider tolerances, as the reference is the object itself, and not a CAD drawing.

“Our close cooperation with shipbuilders has shown us that there is a demand in the market for automated systems that provide more efficiency and better weld quality. It gives us access to detailed knowledge of welding processes and equipment. Combining this with our knowledge of welding technology gives us the opportunity to continuously develop our innovative solutions.” – Skjølstrup.

Now more than ever, shipbuilders need to innovate constantly and remain adaptable to survive and expand. As we head into 2024, they will rely heavily on technology and innovation to break new ground, with turnkey welding solutions at the heart – all of which makes 2024 an exciting time for welding automation in shipbuilding.