The growing need for skilled welders in offshore wind and shipyards worldwide has placed a huge demand for labor in these sectors. Numerous manufacturers experience a lack of efficient, high quality welding solutions for large and complex structures.

For example, some wind projects can span two to three years, and a single project can easily require 100 full-time welders on the job as the structures that has to be welded are increasing both in size and complexity.

Ask just about anybody involved in manufacturing about hiring, and they’ll probably all eventually say the same thing: a qualified welder is hard to find. Actually, all qualified welders are hard to find.

The years-long shortage of welders is showing no signs of easing up. According to American Welding Society, the industry will face a shortage of about 400,000 welders in US by 2024.

As a result, manufacturers are doubling down on their efforts to expand training options and secure partnerships with training schools. Older welders are also reaching retirement age, and younger welders aren’t replacing them fast enough. In fact, the average age of a welder is 55, and fewer than 20 percent are under the age of 35. (American welding Society).

Access to a skilled, proven welding workforce has never been more important. As the nation’s infrastructure continues to age, construction contractors will require proven welders to rebuild structures, bridges and roadways. Skilled welders will also be an asset to the offshore wind and oil and gas industries, where they work on pipelines, wind turbines and other energy delivery sources.

Technology to improve weld quality and productivity

These challenges can be addressed if the right welding solutions are implemented – welding solutions that can replicate the skills of a manual welder and provide a welding method that has the ability to follow an approved welding procedure and plan the weld sequence just like a welder would do, as well as producing high quality welds.

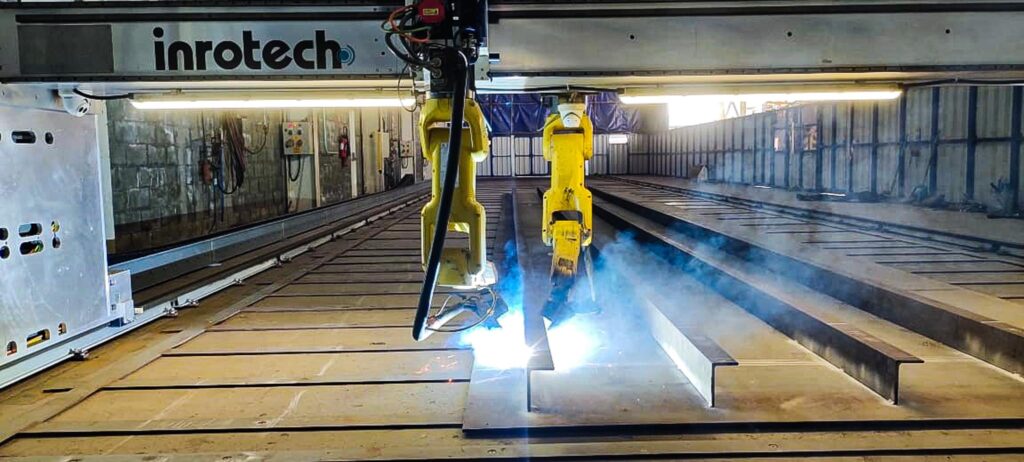

To address these challenges and meet project deadlines with a shrinking pool of skilled welders, Inrotech has developed various solutions and technologies that has proven to be the solution.

Inrotech offer several advantages to traditional gantry-based solutions; lower cost, less transport of large structures and flexibility to move to a variety of working zones. Rasmus Faudel, System & Software Manager of Inrotech explains “we specialize in bringing the robot to the job, rather than the traditional method of bringing the job to the robot. This philosophy is the only way you can achieve automated welding on some of the very large structures we now experience in heavy industries”.

Data analytics and reporting are also important aspects for manufacturers in heavy industries as they look to improve data management. The fact that manual welding will be a thing of the past highlights the importance of intelligent welding data storage.

One of the immediate advantages of weld data storage is that it provides a record of quality control. If a structure or project should fail later in the process, weld data provides a record that proves that the weld was made in accordance with provided weld parameters and that it met project requirements. This helps to shield the manufacturer that made the weld from any liability for project failure.

In this regard Inrotech has developed a new cloud solution that allow us and our customers to collect data and performance readings. This to visualize results from robot welding projects, which can then be used to improve welding installations – a solution not many welding machine manufacturers offer, despite the increasing customer demand.